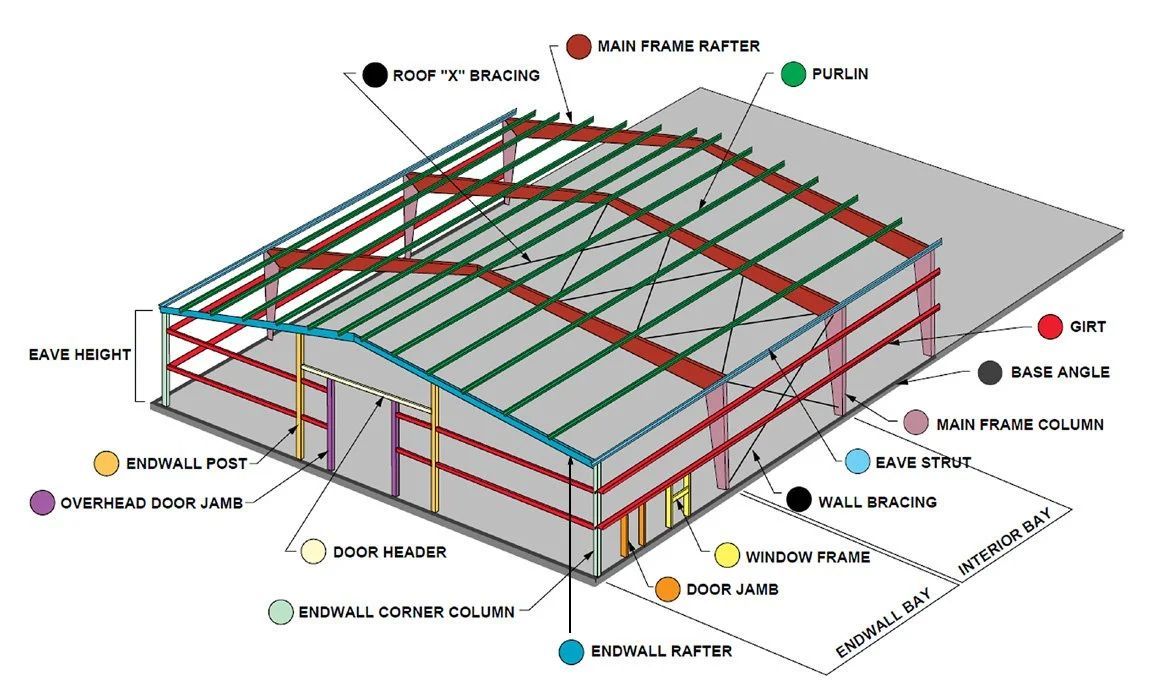

The anatomy of a pre-engineered steel building

Modern metal structures consist of a series of framing systems that support roof and wall panels to create strength, stability and open space freedom.

When people drive by a pre-engineered metal warehouse or other industrial building, they understand inherently how the construction works. A steel frame sits atop a concrete foundation and is shelled by insulated metal panels and a steel roofing system. But the engineering is more than that. Steel buildings maintain their strength, stability and energy efficiency through a number of framing systems that reinforce each other. Let’s explore the difference between primary and secondary framing, and how steel is the ideal building system for commercial construction.

The leadership team at Summit Steel Buildings is dedicated to providing the best quality building solutions possible – custom-suited structures for every client’s need and built to last for generations. Improving steel buildings through stronger and more corrosive-resistant steel is our passion.

In fact, we are part of an on-going corrosion research project working with PhDs in electro- and analytical chemistry and metallurgy from Western University, University of B.C. and Canada’s particle accelerator centre. Our team is working with other cross-disciplinary experts to determine how steel can be modified and enhanced to reduce or prevent corrosion and extend the life of steel buildings, especially in wet or harsh environments.

As structural engineers and steel builders, we rely on a variety of metal framing systems using I-beams to make our facilities so strong, long-lasting and durable. Our pre-engineered metal buildings are engineered as complete, integrated systems – designed to work together for efficiency and long-term performance. At the core of every building is highly optimized steel framing that delivers exceptional structural stability while enabling wide-open interior spaces with few – or no – interior columns.

This article is part of our "get to know the components in a building system" series. Learn more about

purlins,

girts,

insulated metal panels,

insulation,

concrete foundations, exteriors

and

roofing systems and

roofing panels.

Two types of framing systems that make metal buildings so durable

Primary framing forms the structural backbone of a pre-engineered steel building. This includes the main steel columns and rafters (beams) – typically tapered I-sections that are deeper where loads are highest and lighter where they are not. This variable geometry is one of the key reasons metal structures are both strong and material-efficient and can reach enormous dimensions. Primary frames transfer roof, snow, wind and seismic loads directly through to the concrete foundation.

Common primary frame configurations include:

- Clear span frames, which eliminate interior columns entirely

- Multi-span frames, used when extremely wide buildings require intermediate supports

- Gable and single-slope frames, selected based on drainage, site conditions, and architectural intent

Supporting the primary structure is secondary framing, which provides load distribution and enclosure support:

- Purlins span between rafters to support roof panels

- Girts span between columns to support wall panels

- Eave struts tie the roof and wall systems together at the building perimeter

Together, these elements create a rigid yet flexible skeleton that is engineered for the project’s exact dimensions, usage, location and environmental loads.

Bracing, enclosure and long-term stability

Pre-engineered metal buildings rely on engineered bracing systems – including rod, flange or diaphragm bracing – to resist lateral forces from wind and seismic activity. Roof and wall panels (typically 26-gauge steel with high-performance coatings) also contribute to overall diaphragm strength while providing weather protection and durability.

Because every component is pre-designed and fabricated to precise tolerances, the finished building performs as a unified structural system rather than a collection of independent parts.

Why clear-span steel framing changes what’s possible

Clear-span steel frames are one of the most powerful advantages of pre-engineered building construction. By transferring loads efficiently through rigid frames instead of interior columns, our buildings unlock uninterrupted floor space and unmatched interior flexibility.

Because of the column-free space clear-span engineering creates, pre-engineered buildings are ideal for many commercial and industrial uses where traditional construction is not possible.

- Aircraft hangars, where unrestricted movement and storage are critical

- Sports arenas and recreational facilities, enabling unobstructed sightlines and flexible layouts

- Tennis, soccer and riding arenas, creating safe, open environments for athletes and animals

- Manufacturing and warehouse facilities, where machinery, conveyors and forklifts require clear circulation paths

- Office and retail spaces, where open layouts enhance customer experience and allow future reconfiguration

And expandable end-wall engineering allows your structure to meet today’s needs while remaining adaptable for tomorrow’s growth.

Build smarter with a purpose-designed steel structure

A pre-engineered steel building is more than a shell – it is a precisely engineered framework designed to maximize usable space, structural performance and long-term value.

Summit Steel Buildings specializes in custom metal structural solutions for commercial and industrial clients across North America. Their team works closely with owners, architects and engineers to design steel framing systems – whether clear span, multi-span, or hybrid – that align perfectly with operational goals, site conditions and future expansion plans.

If you’re planning a new facility or upgrading an existing one, Summit Steel Buildings can design and supply a steel building system tailored exactly to how you work today and how you plan to grow tomorrow.

Speak with Darren Sperling by telephone at 877-417-8335 or contact us online and he’ll be happy to provide you with a free consultation and quote. We'll also be happy to provide you with preliminary drawings.

About the author

Darren Sperling has specialized in the engineering and delivery of pre-engineered steel buildings for over 20 years and has experience in over 20 countries worldwide. He can be contacted at Summit Steel Buildings at (877) 417-8335, by email at darren.sperling@summitsteelbuildings.com or on LinkedIn.