Pre-engineered steel building design drives operational efficiency

Adding new capacity with ideal work layouts increases strategic value and competitive advantage for industrial and warehouse enterprises.

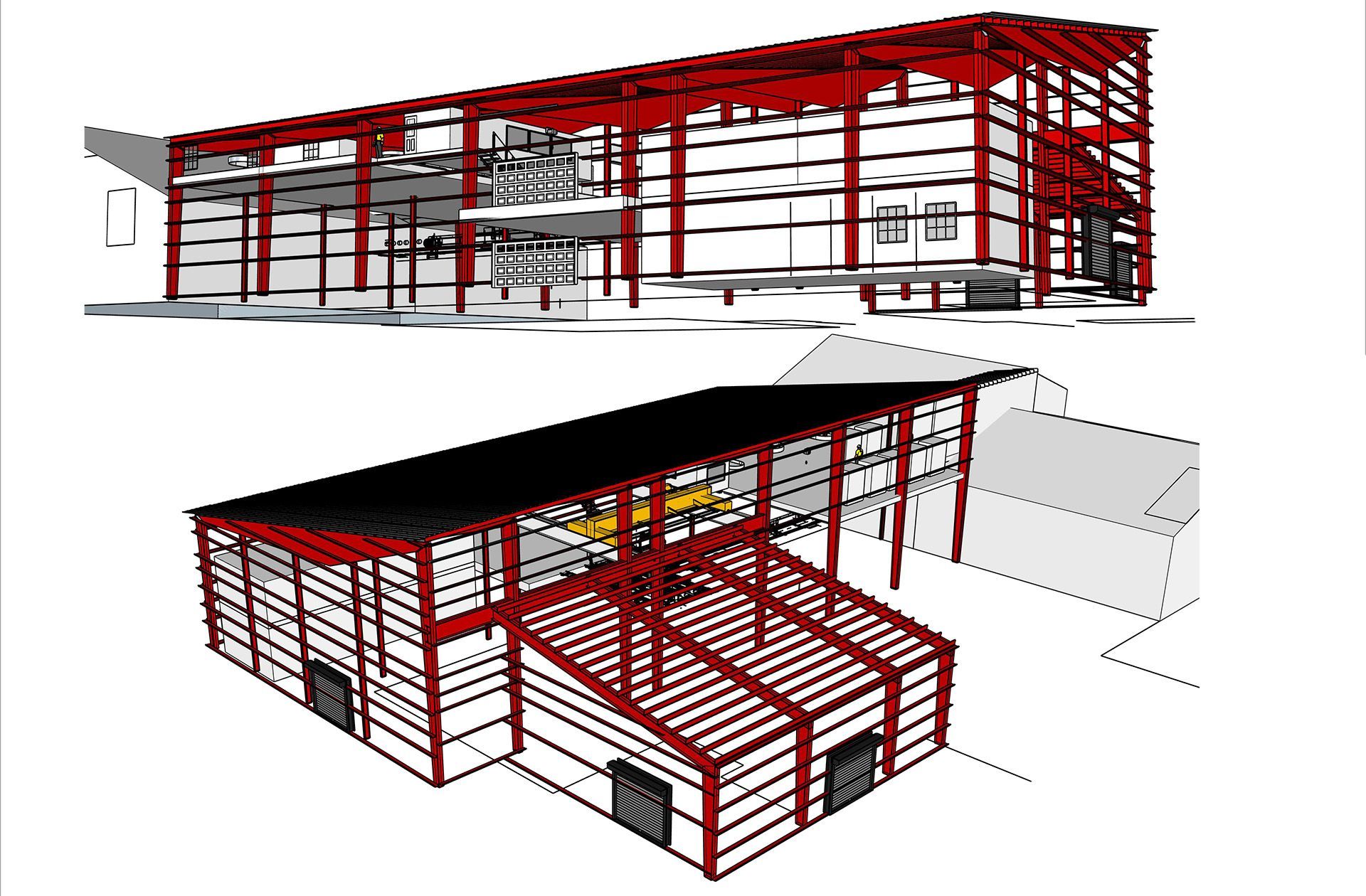

For competitive industrial markets where controlling costs is vital, facility performance is no longer measured solely by construction cost or architectural appeal. Enterprises are placing greater emphasis on operational efficiency, process optimization and lifecycle value – and pre-engineered steel building (PEB) systems are uniquely positioned to deliver across all three. This means that when engineering and architectural firms work with Summit Steel Buildings, they are assured to have their design visions manufactured and constructed with absolute precision so buildings are completed affordably with long-term performance that results in lower operating costs and better value.

Beyond aesthetics: Engineering for function

Traditional construction methods often prioritize appearance or traditional form factors at the expense of performance. Pre-engineered steel buildings, by contrast, can offering both, beginning with engineering fundamentals that align with the facility’s operational purpose:

- Load-driven design: Structural components are optimized based on actual functional requirements (e.g., storage densities, equipment loads, crane systems) rather than prescriptive templates.

- Clear span efficiency: Steel trusses and optimized girts allow expansive interior spaces with minimal columns, facilitating storage system layouts, automated material handling and unimpeded circulation.

- Precision engineering: Advanced building information modeling and fabrication tolerances reduce field modification, ensuring that as-built conditions align with intended design – a crucial factor for ideal workflows.

Remembering to anticipate function as well as form ensures the building envelope supports real business processes – not just design aspirations. The result is an industrial complex (whether it be for

manufacturing, logistics or

storage) that works the way operations are intended to run.

Reducing waste through integrated design

Traditional Waste in industrial construction isn’t only about materials – it’s about time, mismatches between design intent and execution, and inefficient coordination among disciplines. Summit Steel Buildings’ use of pre-engineering design reduces this waste in several ways.

1. Precisely controlled custom manufacturing

Each pre-engineered component is manufactured in a controlled environment with high precision. This approach minimizes on-site rework, reduces schedule risk from weather delays and enhances quality control – all essential for planning and adhering to tight operational timelines.

2. Digital coordination to avoid disruption to timelines

Using Building Information Modeling (BIM) early in the design process with architects allows mechanical, electrical, structural and architectural systems to be coordinated well before fabrication. This arrangement helps flag possible potential interruptions prior to construction, reduces material waste and prevents unnecessary revisions and change orders.

For industrial clients, it also ensures that specialized systems (like dock equipment, mezzanines or conveyor supports) are integrated without costly retrofits.

3. Optimizing materials to reduce waste and costs

Steel’s predictable mechanical properties and modular detailing support efficient design decisions that directly translate to less materials and waste. Summit Steel Buildings’ engineers can tailor member sizes to match loads rather than adopting uniformly oversized sections – reducing embodied energy and cost without sacrificing performance.

Intelligent layouts help enhance workflows

Warehouse and industrial workflows are deeply affected by building geometry, circulation paths and spatial organization. Pre-engineered steel design using column-free clear spans enables:

- Optimized circulation aisles that align with forklifts and automated guided vehicles (AGVs)

- Loading dock configurations that minimize turnaround time

- High clearances and stacking zones to maximize vertical storage

Because steel structures support

wide clear spans and flexible bay spacings, planners can configure space in ways that directly mirror operational priorities rather than contorting operations to fit the building constraints.

Gains in productivity help shorten the payback period of your investment

Pre-engineered building design gets building construction completed and into operation as soon as possible, which leads directly to financial gains. These can be measured in terms of reduced handling times and reduced maintenance downtime.

- Reduced handling time: Clear span layouts and optimized circulation reduce product travel distances and bottlenecks.

- Fewer maintenance interruptions: Steel’s durability and engineered connections reduce long-term facility maintenance disruptions.

- Accelerated commissioning: Precise fabrication and coordination mean facilities are ready for operations earlier with fewer punch list items.

From a financial statement standpoint, these improvements are not incremental – they can translate into higher throughput, lower operating costs and improved time-to-market for distributing products.

An investment into improved or more facilities translates directly into operational gains

Pre-engineered steel building design is not a commodity choice – it is a strategic investment in operational performance. By integrating custom engineering and operational planning into the earliest phases of design, organizations gain facilities that are optimized for real process flow, less wasteful in construction and operation and more productive over their lifecycle.

For architectural and engineering firms, as well as industrial enterprises, the message is clear: when operational efficiency matters, function must precede form – and pre-engineered steel delivers on both.

Whether redeveloping existing buildings and structures or creating new ones from the ground up, Summit Steel Buildings strives to ensure the result is consistently above and beyond expectations. Their friendly team is happy to assist in finding the perfect building solution for any storage or operational need. Don’t hesitate to contact Summit Steel Buildings for your free consultation and quote. They’ll also be happy to provide you with complimentary preliminary drawings.

About the author

Darren Sperling has specialized in the engineering and delivery of pre-engineered steel buildings for over 15 years and has experience in over 20 countries worldwide. He can be contacted at Summit Steel Buildings at (877) 417-8335, by email at darren.sperling@summitsteelbuildings.com or on LinkedIn.