Build local to avoid tariffs and spend less

The advantages when you use domestic manufacturing from Summit Steel Buildings.

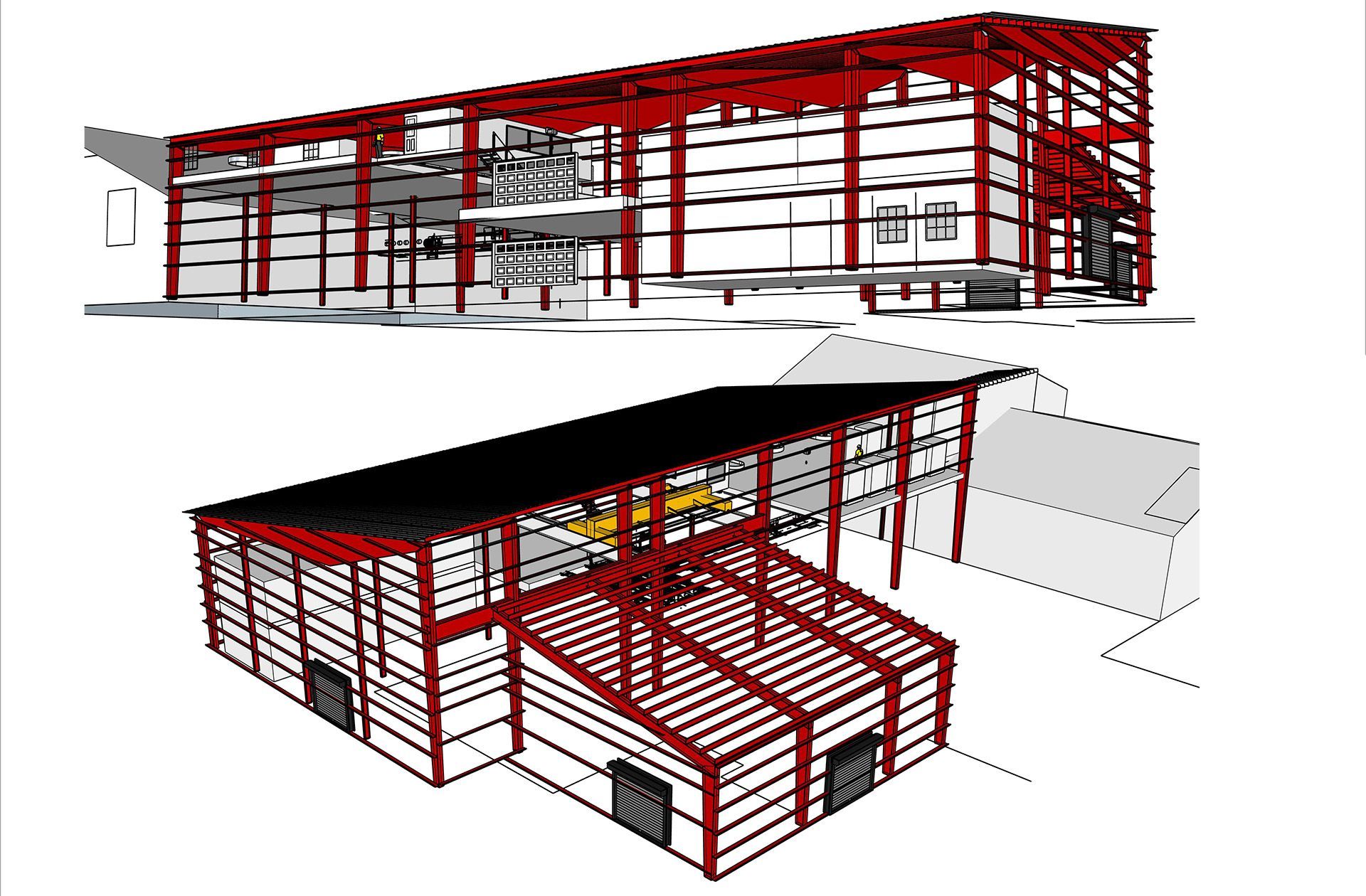

Across North America, Summit Steel Buildings delivers high-quality pre-engineered metal buildings (PEMBs) with a strategic manufacturing model designed to save clients money, reduce risk and keep projects on schedule. Whether your project is in the United States or Canada, every component of your building is produced domestically – as close to your jobsite as possible – through our network of regionally based steel factories.

The result:

lower costs, fewer complications and faster, more dependable delivery and construction.

Manufactured close to home – for your benefit

Summit Steel Buildings operates throughout the continent using four steel manufacturing plants in the U.S. and two major factories in Canada. We manufacture in the country where your project is being built, ensuring that every wall panel, roofing system and structural component comes from a domestic source.

This localized approach means you avoid the financial and logistical challenges that come with cross-border procurement, including:

- Tariffs and customs fees

- International shipping costs

- Unpredictable currency exchange rates

- Complex import documentation

- Border delays that potentially stall construction schedules

By keeping production within national borders, we streamline the entire process – and pass the savings on to you.

Lower costs through streamlined logistics

Manufacturing components and roof/wall systems as close as possible to your jobsite dramatically reduces transportation expenses and shortens delivery timelines. Our proximity-based logistics model offers:

- Faster lead times and reliable delivery

- Reduced freight charges

- Improved coordination for phased material drops

- Better alignment with project schedules

This efficiency directly supports smoother construction management and more predictable budgeting for commercial, industrial and architectural projects.

Financial stability your business can build on

In today’s volatile market, domestic sourcing offers meaningful financial protection. By producing your building systems within the same country where your project is located, Summit Steel Buildings helps you:

- Eliminate exposure to USD/CAD exchange rate swings

- Avoid international shipping surcharges

- Prevent surprise tariffs or duties

- Maintain a simplified local tax structure

For engineering firms, architects, developers and commercial operators, these financial safeguards create greater predictability – and fewer budget overruns.

Better quality, better control, better outcomes

Local manufacturing doesn’t just reduce cost and complexity; it strengthens project execution. Building in the same jurisdiction allows for:

- Direct oversight and relationships with us as your one specific and domestic manufacturer

- More responsive design changes

- Shorter reaction times when schedules shift

- Easier compliance with regional building codes and standards

This level of control helps ensure that each project is delivered accurately, efficiently and to the highest engineering standards.

A strategic advantage for North American clients

In both Canada and the United States, clients are increasingly choosing domestic PEMB solutions to minimize risk and maximize long-term value. Summit Steel Buildings is driving his shift by combining early procurement strategies with regionally aligned manufacturing capabilities.

Our approach delivers:

- Greater price stability

- Faster project delivery

- Reduced environmental impact from shorter transport routes

- Stronger alignment with sustainability and local-industry mandates

Build with confidence while supporting your domestic economy

Choosing Summit Steel Buildings means choosing a smarter, more predictable approach to construction. By manufacturing everything as close to your project as possible, we help you lower costs, navigate economic uncertainty and keep schedules on track – while supporting the strength of your local manufacturing sector.

Domestic manufacturing isn’t just a supply strategy – it’s a competitive advantage.

And Summit Steel Buildings puts that advantage to work for you.

For free quote and

preliminary drawings suited to your specific location and business need, please use our

webform, send us an

email or call us at

877-417-8335. We're excited to speak with you and help develop your ideal pre-engineered building solution.