Pre-engineering: Better for safety and efficiency

Modular steel construction for new or expanded facilities minimizes on-site risks and keeps projects moving so operations start safely on time and without costly delays.

Written by

Frank Melo

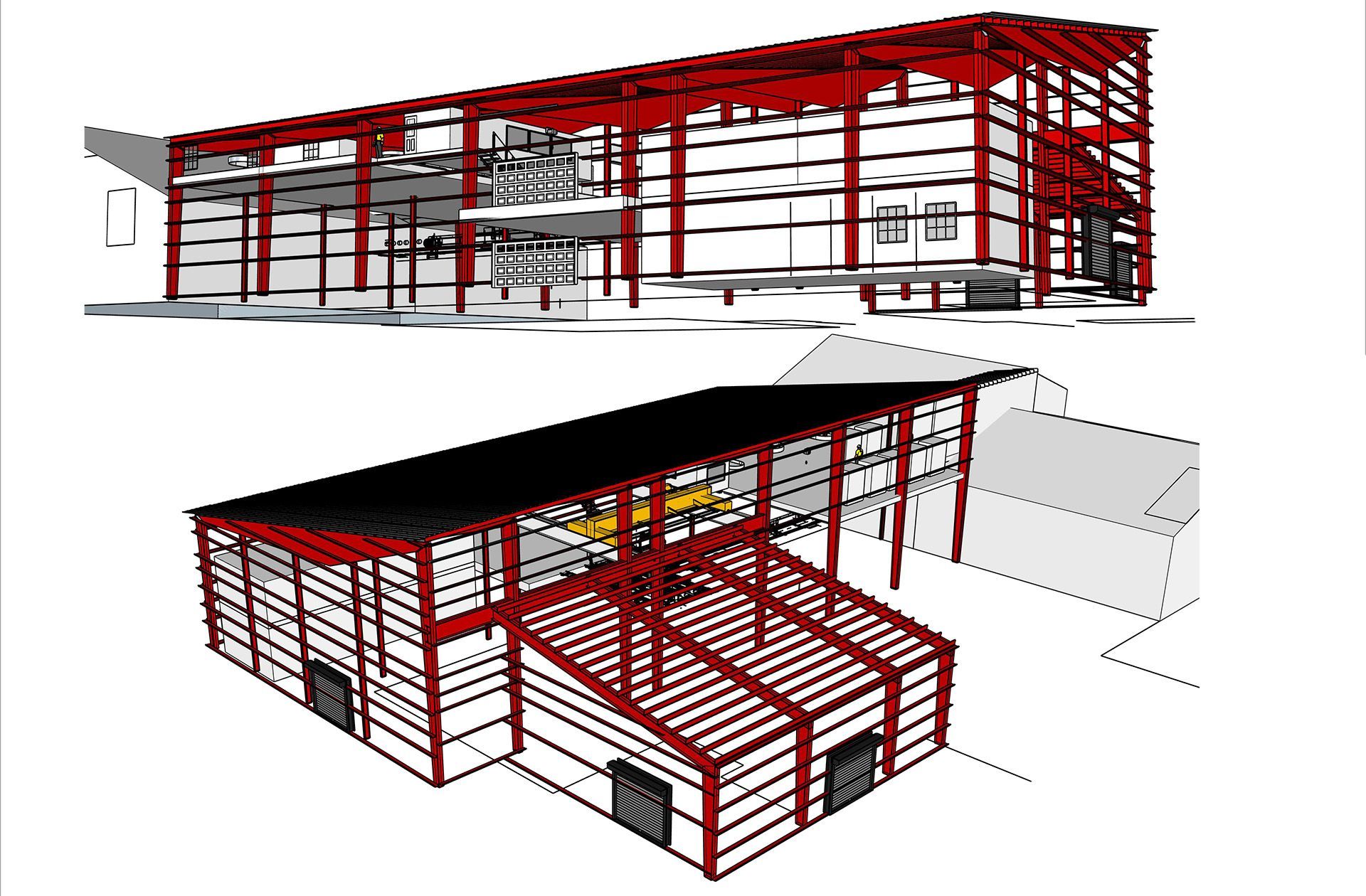

In commercial and industrial sectors where risk management and efficiency can help define success, pre-engineered steel construction has emerged as the solution of choice. Relying on manufacturing steel wall and roof systems off-site, assembling them into larger components and shipping to site for installation, helps project owners cut timelines and costs. And an additional benefit is the reduction of other potential hazards where any delay could result in a financial hit.

When companies require custom-designed infrastructure to increase storage or working space, using a turnkey building solution partner that prioritizes safe and speedy construction is the intelligent choice.

Reducing on-site risk

Falls are the single largest contributor to injuries in the construction industry. According to safety data, using pre-engineering construction methods can reduce at-height labour requirements by as much as 30 to 50 per cent, significantly decreasing the probability of fall-related incidents. For the leadership team at Summit Steel Buildings, who are each single-minded about the well-being of their tradespeople, the implications are clear: a safer and happier worksite, fewer disruptions, lower insurance exposure and a safety record to strengthen corporate reputation. It also means lower costs and an absence of deadline delays for clients. Everyone wins.

Reducing challenges unique to geographic constraints

Canada’s climate and geography present their own construction difficulties. Golf and ski resort projects often face immovable seasonal deadlines, while remote mining and warehousing facilities operate in regions where logistics are both costly and unpredictable. Using pre-engineered steel components moves the bulk of manufacturing into controlled environments ahead of transportation to reduce weather delays and ensures higher-quality assembly. The result is a streamlined process that delivers completed structures faster, at predictable cost and with fewer contingencies.

A strategic advantage for decision-makers

We know that predictability is fast becoming a core value driver for executives evaluating capital projects . The pre-engineered approach does more than accelerate completion: it reduces exposure to on-site hazards, curtails unplanned overtime and safeguards margins. In an era where investors and regulators alike scrutinize safety and ESG performance, modular steel offers an operational hedge that extends well beyond construction sites.

Prioritizing safety, time and savings using intelligent engineering

Pre-engineered Summit Steel Buildings, recognized for its incident-free installation record, has positioned itself as a leader in delivering pre-engineered metal structures for both industrial and commercial applications. For companies exploring new or expanded facilities – whether

a processing hub or warehouse in a mining district or a

clubhouse expansion at a golf course

– the question is less whether pre-engineering methods work, and more how much they can save in time, safety and capital. Don’t forget to ask how our pre-engineered metal building solutions can be used to

revitalize older buildings.

Contact Summit Steel Buildings to discuss your construction and business needs. We’ll provide you with preliminary designs and an affordable price to support your future business operations. Reach our team online, by email at info@summitsteelbuildings.com or at 877-417-8335.

About the author

Frank Melo has a construction civil engineering technology and business background with over 30 years of experience as a business owner and contractor. He was raised and educated in London, Ontario and now divides his time between projects primarily in Ontario and British Columbia. He can be contacted at Summit Steel Buildings at

(778) 951-4766 or by email at

frank.melo@summitsteelbuildings.com

or through

LinkedIn.