Steel at the water’s edge

Modern maritime and waterside facilities are being engineered for performance, durability and experience.

The modern waterfront tells a different story than it did a generation ago. Today’s ports, marinas, and maritime hubs are no longer purely utilitarian places of work. They are operational engines, economic anchors, and – more often than ever – destinations.

From a dockside restaurant on Vancouver Island to a cruise terminal in Nova Scotia or a marina resort in the Caribbean, maritime and lakeside businesses are investing in better infrastructure to serve demanding operational needs while improving customer experience. At the center of this evolution is a building system uniquely suited to coastal realities: the pre-engineered steel building.

Once clients realize how metal structures are ideal for all-season purposes, they turn to

Summit Steel Buildings – a premier supplier for industrial and commercial businesses across North America.

Better structures for modern marine businesses

Maritime and lakeside operations are among the most diverse and demanding in the built environment. A single port or harbor may support several overlapping business types, each with distinct space, durability and regulatory requirements. Warehousing makes up the biggest demand for port authorities.

Common commercial and industrial activities requiring ideal storage and workshop structures across the marine sector include:

- Shipping, transportation and logistics (container handling, bulk cargo, intermodal transfer)

- Fishing and seafood processing (fleet storage, equipment maintenance, cold storage)

- Boat storage and repair (seasonal storage, dry stacks, service bays)

- Fuel storage and marine supply (diesel, LNG, lubricants, chandlery)

- Passenger and cruise operations (terminals, ticketing, security, customs)

- Tourism, recreation and hospitality (marinas, waterfront restaurants, clubs, resorts)

Each of these core maritime business segments rely on structures that must withstand moisture, salt damage, wind, corrosion, heavy loads and constant use – while remaining visually welcoming to the public.

Ideal building types for maritime operations

Steel building systems are increasingly used to house and enhance:

- Boat storage facilities with long clear spans for sailboats, yachts and commercial vessels – get the insulated, climate-controlled and protective environment clients demand

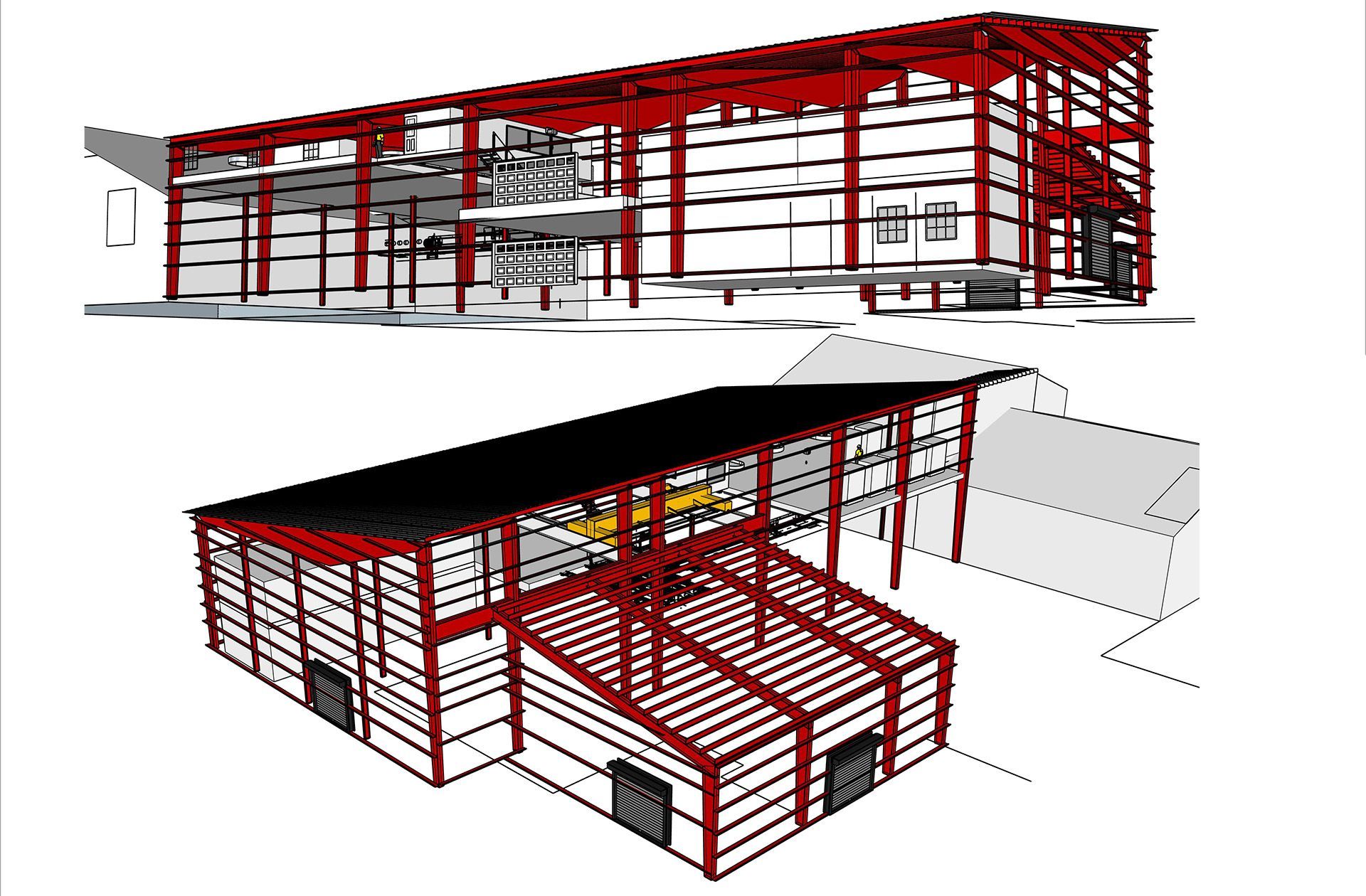

- Maintenance and fabrication shops with overhead cranes and tall bay heights

- Fuel storage and supply buildings designed for safety, ventilation and compliance

- Port warehouses and logistics hubs optimized for throughput and equipment flow

- Administrative offices and terminals integrated directly into port operations

- Hospitality and guest-experience buildings, such as waterfront restaurants, lounges and event spaces

Whether supporting year-round commercial activity on the Great Lakes or seasonal tourism in Nova Scotia, these structures form the backbone of marine business success.

Why pre-engineered steel outperforms traditional construction on the coast

Maritime environments are unforgiving. Salt air and water exposure, humidity, freeze-thaw cycles, hurricanes and heavy snow loads all place stress on conventional buildings. This is where pre-engineered metal buildings (PEMBs) offer a clear advantage over brick-and-mortar or wood-based construction.

Structural and economic advantages

Pre-engineered steel buildings provide maritime operators with:

- Superior corrosion resistance through modern coatings and engineered detailing

- Long clear spans that maximize usable floor area for vessels and equipment

- Faster construction timelines, reducing downtime and lost seasonal revenue

- Lower lifecycle maintenance costs, particularly in saltwater environments

- High wind, seismic and snow-load performance, critical for coastal regions

For example:

- On Vancouver Island, steel structures perform reliably in wet, temperate climates while accommodating fishing fleets and recreational marinas.

- In Nova Scotia, PEMBs are engineered for heavy snow loads, high winds and freeze-thaw durability.

- Across the Great Lakes, steel buildings support large-scale seasonal boat storage and logistics operations with predictable performance.

- In the Caribbean, locations such as Jamaica or Trinidad and Tobago benefit from hurricane-rated steel systems that resist rot, pests and humidity.

Design freedom and new revenue opportunities

Modern steel buildings are no longer industrial boxes. With architectural façades, glazing, canopies and integrated interior finishes, PEMBs can support high-end public spaces – such as waterfront dining rooms, cruise terminals and marina clubs – without sacrificing structural efficiency.

This flexibility creates tangible business value:

- Increased storage density allows operators to winterize and store more boats per square foot.

- Expandable designs enable future growth without relocating operations.

- Multi-use facilities combine storage, service, retail and hospitality under one roof.

For many maritime businesses, these efficiencies shorten payback periods and unlock new revenue streams – from off-season storage and maintenance programs to year-round event and hospitality offerings.

Future-ready ports and marinas: Building for operations and experience

Port authorities and maritime operators face increasing pressure to modernize infrastructure while improving customer experience, safety and sustainability. Steel building systems make this possible without overcapitalizing projects or extending construction timelines.

Integrated steel solutions allow ports and marinas to:

- Improve vessel flow and operational efficiency

- Enhance passenger and guest amenities

- Consolidate functions into fewer, better-performing buildings

- Plan phased expansions with minimal disruption

Summit Steel Buildings offers strategic advantage

Our structures provide a fully integrated service offering – engineering, manufacturing coordination and turnkey construction – tailored to commercial and industrial clients across North America. Their pre-engineered building systems are designed for performance, speed and adaptability, giving particular strength in challenging environments such as coastal and maritime regions.

Key advantages include:

- Engineering expertise aligned with regional climate and code requirements

- Custom-designed steel systems optimized for operational efficiency

- Reliable project execution through coordinated supply and construction

- Expandable, future-ready designs that protect long-term capital investment.

A call to build at the water’s edge – with confidence

From working harbors to luxury marinas, the future of maritime infrastructure is being shaped by smarter, stronger and more adaptable buildings. Pre-engineered steel systems offer maritime businesses the resilience they need, the flexibility they want and the performance their operations demand.

For port authorities, marina owners and maritime operators looking to modernize or expand, the next step is clear: partner with a building system provider who understands both engineering and the realities of life at the water’s edge.

Summit Steel Buildings stands ready to help maritime businesses build facilities that perform – season after season, tide after tide.

Reach out at, please contact Darren Sperling at 1-877-417-8335 or through our Contact Us page and we'll give you a precise quote and preliminary drawings for your ideal pre-engineered steel structure to help grow and modernize your marine business.

About the author

Darren Sperling has specialized in the engineering and delivery of pre-engineered steel buildings for over 15 years and has experience in over 20 countries worldwide. He can be contacted at Summit Steel Buildings at (877) 417-8335, by email at darren.sperling@summitsteelbuildings.com or on LinkedIn.