Architects deserve a creative platform for modern building design

Architects can transform bold commercial concepts into buildable reality with the power of pre-engineered building systems.

Written by

Frank Melo

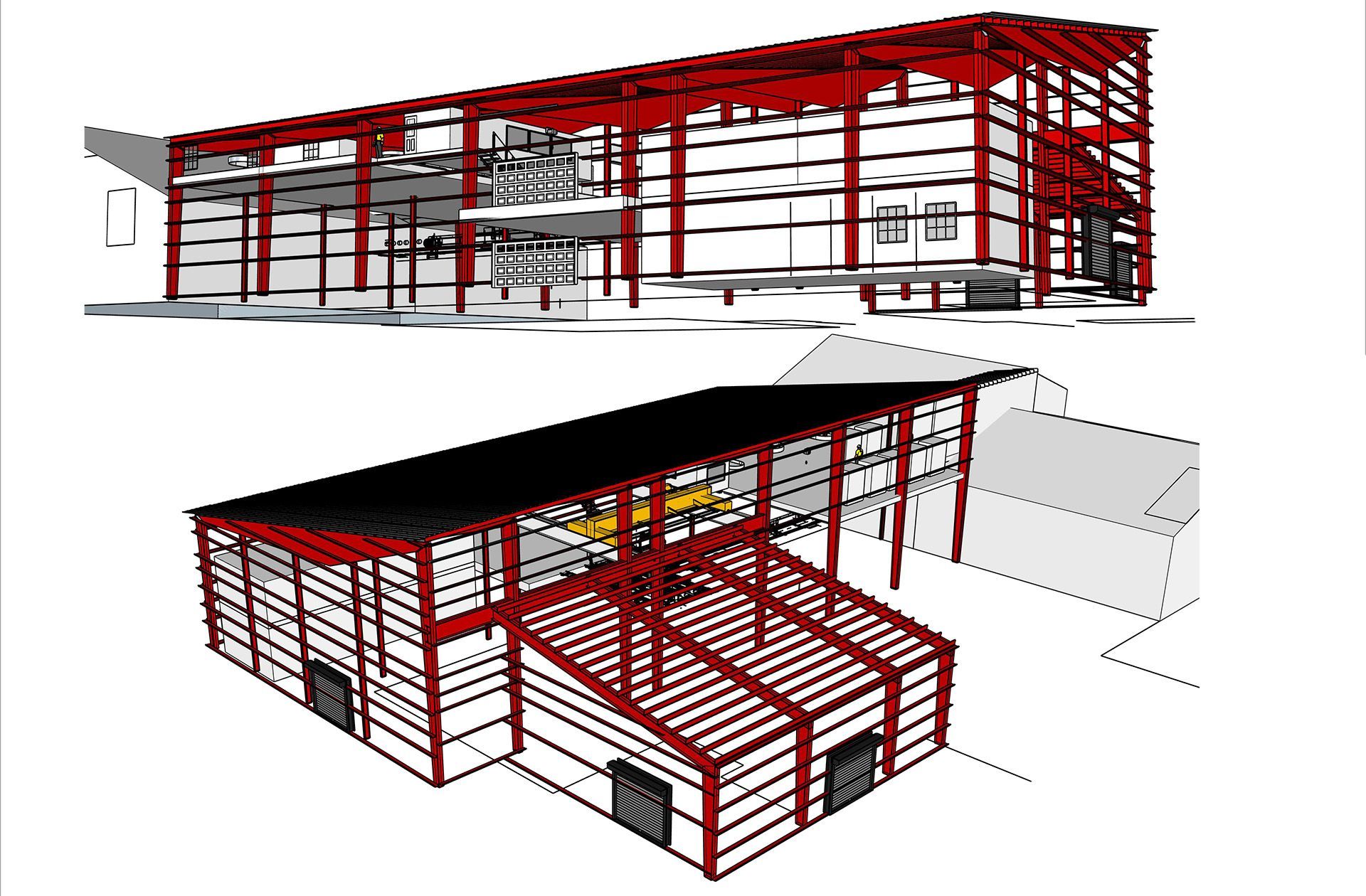

For today’s architects, pre-engineered steel building systems offer far more creative options than the perceived standardized square boxes – they’re one of the most flexible and high-performance design platforms available in the commercial and industrial sectors. With

engineered building systems that balance precision, efficiency and creative freedom, pre-engineering empowers architects to design bold, original structures without sacrificing budget or practicality. Pre-engineered systems let architecture firms bring innovative commercial designs to life with confidence.

A flexible framework for architectural creativity

Modern pre-engineered metal building (PEMB) systems provide a robust structural backbone that can easily adapt to architectural intent. Long clear spans, modular framing, wide-open interiors and extensive customization options allow architects to sculpt space in ways that would be too costly – or even impossible – with conventional construction using wood timber or brick and mortar.

Creative architectural elements such as curtain walls, cantilevers, energy-efficient façades, glass features, multi-storey mezzanines and geometric rooflines all integrate seamlessly with engineered steel frameworks. This versatility gives architects and their clients the freedom to experiment with form while maintaining engineering integrity.

Cost-effective without compromise

What makes PEMBs especially powerful is the synergy between creativity and cost control. Because building components are engineered, fabricated and delivered with precision, waste is reduced, timelines shrink and on-site labour is minimized. This manufacturing efficiency frees up budget that can be reallocated to design and aesthetic enhancements – enabling clients to afford the building they actually want, not just the building they think they can afford.

In other words, pre-engineered steel building systems prove that cost-effective construction does not have to mean cookie-cutter design.

Efficient manufacturing, elevated results

Every Summit Steel Buildings project starts with a digital model that architects, clients and general contractors can refine collaboratively. Once the design is approved, the building’s

structural components are manufactured in controlled environment factories throughout North America, ensuring consistent quality and eliminating common variables that slow projects down. The result is a structure that is durable, energy-efficient and tailored to the project’s vision – from distribution centres to office complexes,

manufacturing plants to retail spaces.

Delivering the client’s vision – beautifully

For clients,

Summit Steel Buildings’ pre-engineered structural solutions offer the best of both worlds: engineering reliability and architectural originality. They get a structure that performs exceptionally, respects the budget, accelerates timelines and

still reflects their brand, purpose and character.

For architects, working with pre-engineered steel buildings opens the door to new possibilities – transforming a proven structural system into a canvas for innovation.

Contact Summit Steel Buildings to discuss your design concepts and share your building plans with our team. We’ll provide you with preliminary technical drawings and a cost-effective price to support your architectural work with clients. Reach our team online, by email at info@summitsteelbuildings.com or at 877-417-8335.

About the author

Frank Melo has a construction civil engineering technology and business background with over 30 years of experience as a business owner and contractor. He was raised and educated in London, Ontario and now divides his time between projects primarily in Ontario, British Columbia and Washington State. He can be contacted at Summit Steel Buildings at

(778) 951-4766 or by email at

frank.melo@summitsteelbuildings.com or through

LinkedIn.