Why build with steel when wood is readily available?

Forestry operations rely on metal structures to provide the durability they need in Canada’s wildest environments.

Wood is one of the most versatile building materials. It’s affordability and availability have made it a valuable component of residential construction around the world. Canada’s abundant supply of sustainable forests help drive one of our economy’s most valuable industries. The forestry and timber sectors are a leading contributor to our nation’s healthy employment level and in growing the country’s GNP.

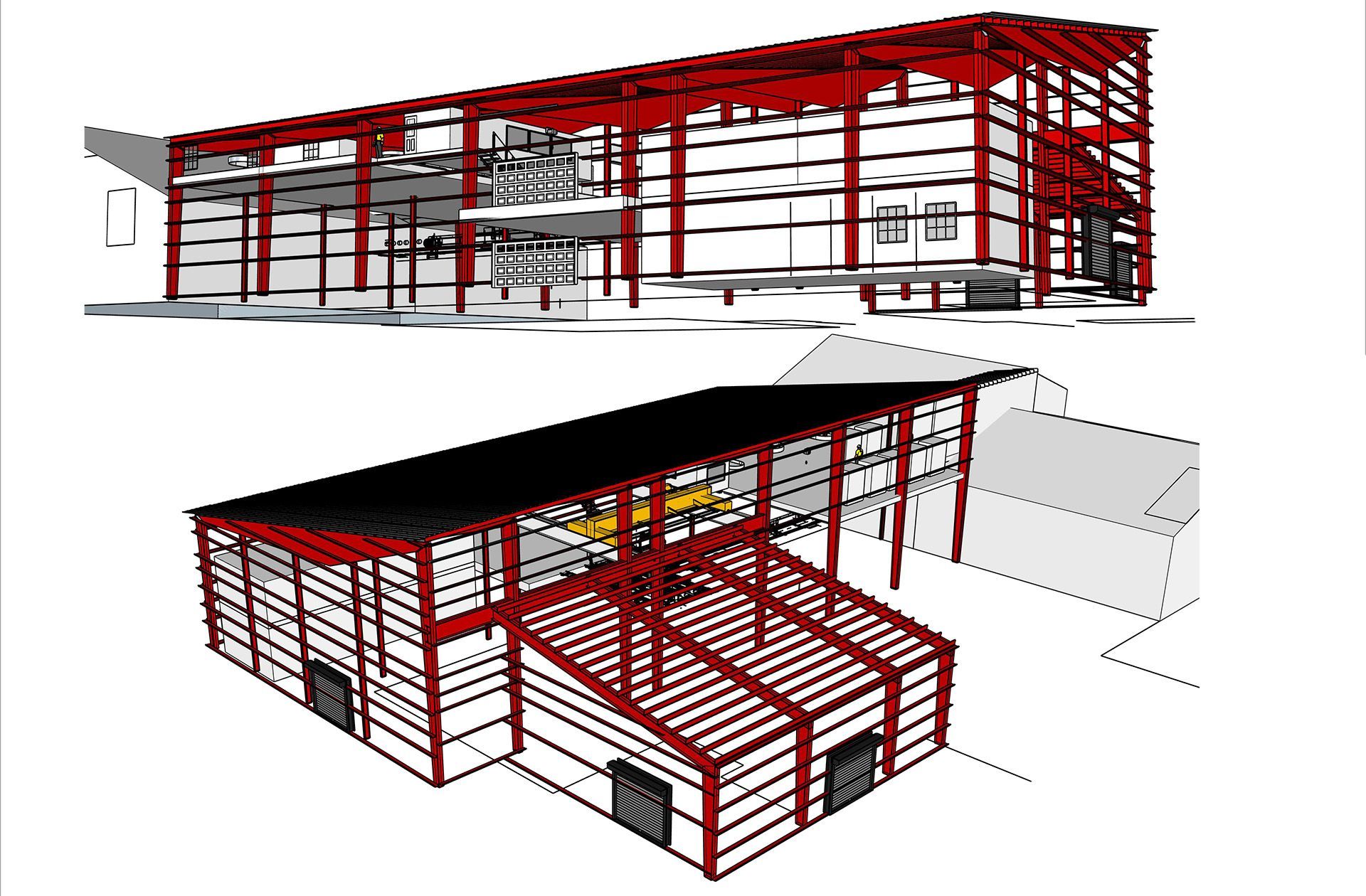

While wood framing forms the basis of residential buildings, such as bungalows and two-story structures to be overlaid with brick or siding, larger industrial facilities require steel. The metal’s higher strength-to-weight ratios are better suited to supporting much larger structural loads and to provide the protection against much harsher weather conditions. Heavy steel beams and girders provide wider spans and higher clearances to provide the wide-open spaces warehousing and processing requires for safety and freedom of movement. On a larger industrial scale, the cost of effectiveness and durability of using steel make it a better building material than timber. Read about steel buildings made specially for the forestry and timber industries.

Steel gets your building completed faster and stronger

At the outset of any construction project, building requirements focus on getting the final building up and running and producing completed product as quickly as possible. Companies want their finished project to exceed building codes to ensure the greatest possible strength and durability for the long run. Building with steel offers the advantages and benefits your industrial operations require:

1. Lower overall construction costs

Pre-engineered steel buildings use pre-engineered panels to reduce the need for highly specialized labour, use less raw materials, and are manufactured offsite to reduce installation times. Cold-formed steel panels arrive at the construction site pre-welded, pre-cut and pre-hole punched. The metal components are added onto a concrete foundation that provides stability to steel beams and girders, ready to support any R-value insulation. The resulting building is stronger, more durable and more resistant to harsh working conditions and damage – and less expensive. Working with steel is generally 30% less than the price of traditional construction and takes about as third as long to complete.

2. Unlimited design freedom

New facilities need to be built quickly and affordably, often in remote and difficult areas. Pre-engineering means your construction will be completed quickly regardless of how remote the location. Components are built offsite and then shipped in for final assembly.

While fast to build, you don’t have to sacrifice creativity. Most commercial buildings are simple in design with a minimal and efficient layout that’s built to serve a purpose of maximizing space, and to create adaptable, open spaces for working space and storage – but they don’t have to. Industrial clients have so much more choice in design without sacrificing affordability or construction quality. Steel’s versatility and high strength allow building to express a variety of eye-pleasing designs. Pre-engineered metal panels are available in a wide range of exterior finishes and can support as much glass as your vision demands.

Read how adding more production and storage space can increase your operation's profitability.

3. Lower ongoing maintenance costs

Steel buildings use modular-style materials that require significantly less maintenance and are easily replaceable if damaged. Panels are installed with a variety of finishes that do not require painting and do not fade. These allows your team to focus their hours on productive work rather than maintaining the building. Timber structures are prone to long-term deterioration to the elements while steel lasts forever. Never worry about rust or your building losing its “like new” appearance. Lower maintenance costs ensure you maximize the value of your investment.

4. Expand your operations endlessly

Modular building systems mean your steel facility can be expanded quickly and affordably as your needs grow. Traditional construction constricts your footprint, and any addition means plenty of interruption and waste as walls need to be destroyed and rebuilt. Steel buildings use framing bays at one or both ends ensure you can build out or up to extend the life of your construction investment. You never need to worry about outgrowing your building space.

Custom construction that exceeds your expectations

Summit Steel Buildings, Canada’s premier pre-engineered metal structure supplier, builds to suit, whether it's around current equipment or to house recent additions. New buildings are a valuable investment in your company, as much

as your debarker, chip screen, chipper, planer and stacker equipment. We understand your needs and will go the

extra distance to ensure your workflow is planned to maximize production efficiency.

Don’t hesitate to contact us

for a free quote.

About the author

Darren Sperling has specialized in the engineering and delivery of pre-engineered steel buildings for over 15 years and has experience in over 20 countries worldwide. He can be contacted at Summit Steel Buildings at (877) 417-8335, by email at darren.sperling@summitsteelbuildings.com or on LinkedIn.