Indoor farming taking root as key to supplementing food supply

As new and existing food operations see value in growing more food inside, steel buildings have become key infrastructure in the future of farming.

As the demand for fresh year-round local produce continues to rise in Canada, companies are realizing the growth potential and increasing profitability of investing into indoor farming. Also known as precision agriculture or vertical farming, this innovative indoor growing approach to agriculture not only addresses food supply challenges but also promotes sustainability and self-reliance in our local and regional food systems.

Recent news articles have highlighted the potential of indoor farming, which allows producers to reliably grow vegetables and herbs in any climate throughout the year. In particular, growing indoors would allow Canadian organic farmers to keep pace with producing enough product to meet growing demand. And indoor farming is being viewed as an intelligent solution to improve food supply to Northern Canadian communities where access to fresh fruits and vegetables is a major health concern.

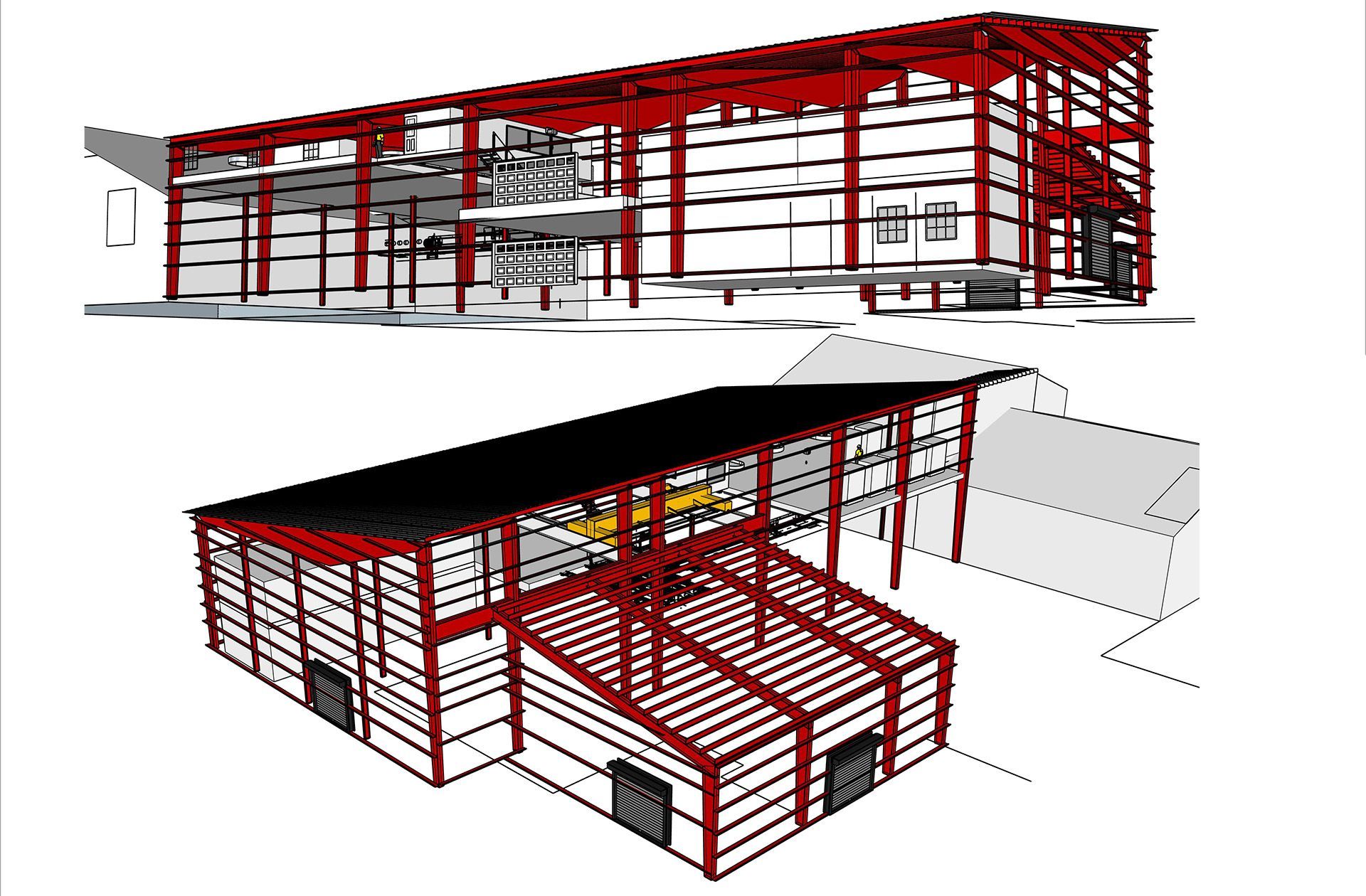

Summit Steel Buildings provide an ideal solution for agricultural operations looking to embark on a vertical farming journey. Our customized buildings are affordable, expandable and designed for low maintenance, making them a practical choice for growers and food manufacturing operations. With complete climate control capabilities, these structures create optimal growing environments throughout the year, allowing for the cultivation of a diverse array of crops, regardless of external weather conditions. Furthermore, their durability and longevity ensure that investments yield ongoing returns, while their scalability allows farmers to expand capacity as size of operations grow.

Canadian food entrepreneurs are adopting indoor agriculture

Success stories abound, showcasing the transformative power of vertical farming. For instance, Avery Farms uses a 50,000 square foot purpose-built facility in Okanagan Falls, BC to produce over 10,000 heads of fresh lettuce daily – 365 days a year. The operation has become a beacon of self-reliant food production in Canada, demonstrating how vertical farming can create sustainable food systems. Their innovative use of space and resources highlights the potential of this farming method to meet local needs effectively.

Similarly, Haven Greens relies on their state-of-the-art, fully automated greenhouse facility in King City, Ontario to revolutionize lettuce production through automation and efficient growing techniques. These two examples are proving that vertical farming can significantly enhance productivity while minimizing environmental impact.

Vertical farming operations using Summit Steel Buildings systems benefit from energy efficiency and the ability to grow food in various environments and conditions, creating much more food resilience and dependability regardless of whatever agricultural challenges face traditional outdoor operations.

Further reading:

- How farm automation is transforming agriculture.

- Effective agribusiness growth starts with steel buildings.

- Protect the herd with steel.

- Free up time: Steel buildings require less maintenance.

- Steel lets you stack your crops.

Building better communities with reliable access to healthy food

As Canada's agricultural landscape evolves, the integration of vertical farming with robust pre-engineered metal structures presents a promising path forward. Most farms and food production businesses can supplement their existing capabilities with indoor production to lower costs and provide reliable access to ingredients. Buildings designed specifically for food enterprises offer secure, easy-to-clean and sanitary conditions with all the necessary water, drainage and energy systems needed. The perfectly controlled temperatures and hygienic conditions require little to no structural maintenance and offer the ability to expand in any direction as food production grows.

To learn more about how your farm or food operation can benefit from an investment into indoor agricultural structures, please contact

Summit Steel Buildings at

877-417-8335 to discuss how cold-formed metal winemaking buildings can contribute to your operation's future success.

About the author

Frank Melo has a construction civil engineering technology and business background with over 30 years of experience as a business owner and contractor. He was born and educated in London, Ontario and now divides his time between projects primarily in Ontario and British Columbia. He can be contacted at Summit Steel Buildings at

(778) 951-4766 or by email at

frank.melo@summitsteelbuildings.com

or through

LinkedIn.