Design considerations: choosing the best framing system for your building needs

No more pillars and posts, build with steel.

How your new building looks from the outside is not simply a matter of architectural design or aesthetic appeal. Your investment needs to have curb appeal to impress visitors because a building’s exterior plays an important role in determining how much open space is available on the inside. Whether for recreation (playing surfaces for sports) or commercial purposes (large open office space or uninterrupted space for warehousing), you can’t allow pillars or posts to get in the way of sightlines or traffic flow.

Engineering and materials have an immense impact on how you build and achieve the unobstructed spaces you need. It’s a key reason why Summit Steel Buildings chooses steel and its high strength-to-weight ratio. Framing and system specifications when building with steel allow your facility to have the large, open spaces (clear spans and bay spans measuring over 300 and 40 feet respectively) that other traditional building materials are not able to support at such a reasonable price. Add in the fact that using pre-engineered metal building framing is 30% less expensive and takes one third as long to complete, the choice to build with steel is clear.

Modern designs require the strength of steel

Although the engineering and system specifications of metal construction allow for impressive architectural design features like broad roof overhangs, cantilevers, walls of glass, large windows and asymmetrical designs, for contemporary commercial buildings, it’s the clean, minimal lines and open well-defined floor plans that are most important. Two factors are responsible for making modern commercial designs possible: joist selection and primary framing systems.

Pre-engineered metal buildings use a “clear bay” system. Long span and open web joists can function as an integral part of the structure’s engineering. If you want open space without posts or pillars interrupting your floorplan, building with steel is the way to go. This style of joists is ideal in supporting floors, roof decks and standing steam roofs. They’re generally more economical when bay sizes are greater than 30 feet or when roof loads are excessive. Other types of joists, such as “K” series, LH or DLH, are normally used when longer spans, between 60 to 120 feet, are needed.

The primary metal framing system creates cost-effective spaces, especially in a multi-story buildings. The building’s final volume is determined by its building shape and roof design. It’s more than just an aesthetic design choice. The shape of the roof can enable higher ceilings, which is a requirement for sports complexes, warehouses and additional second floor space. Roof and framing design help determine how much open, post-free space will be available on the first level.

Framing and roof design shape the space within

Roof design for commercial steel buildings essentially breaks down into two primary categories (although there are many different forms and final layouts that can be created from these general types):

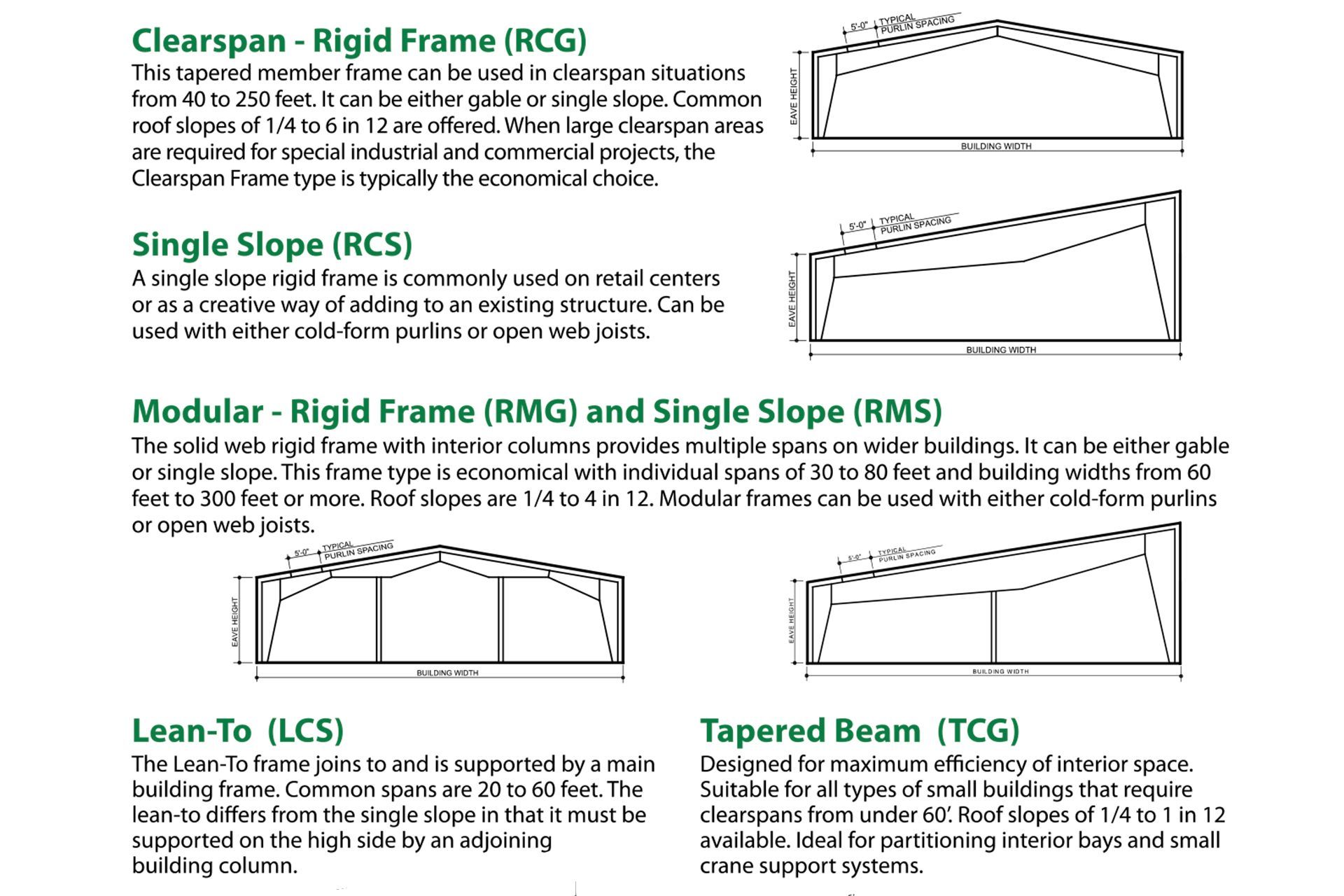

1. Rigid frame clear spans

This style of tapered member frame is generally referred to as a symmetrical gable building. The design includes a single or double slope with the roof ridge in the middle of the structure. These buildings allow for a wide array of design configurations, making them one of the most popular styles. A tapered member frame creates clear spans from 40 to 250 feet. Designed for maximum efficiency of interior space, large areas can be created for special industrial and commercial projects and is typically the economical choice.

2. Single slope

Most common in commercial and retail facilities or as a creative way to add to an existing structure, a single slope rigid frame is a modern sloped roof from one sidewall to the opposite one. This building style is very useful for environments with heavy rain- or snowfall where drainage is a concern. Single slope building designs are a popular choice for storefronts or in office structures where aesthetic appeal is important.

Choose the framing design that suits your purpose

Part of the fun of investing in a new building is the unlimited possibilities. Working with a steel framing system provides unlimited opportunities for contemporary design. Choosing your final building design is a creative process of combining your operational needs with an architectural design that can turn your dream building into a showcase. Your building shape, together with a choice of modern building materials and finishes, provides the occasion to create an ideal working environment.

Summit Steel Buildings creates stunning pre-engineered steel structures that are affordable, beautify and built to last. Working with them turns your vision into reality. Don't hesitate to reach out to us by visiting our Contact Us page so we can discuss the best framing system for your needs and provide you with a free consultation and quote.

About the author

Darren Sperling has specialized in the engineering and delivery of pre-engineered steel buildings for over 15 years and has experience in over 20 countries worldwide. He can be contacted at Summit Steel Buildings at (877) 417-8335, by email at darren.sperling@summitsteelbuildings.com or on LinkedIn.