Eiffel Tower is a surprising precursor to modern pre-engineering

Part 1:

More than just a breathtaking innovation in design, Eiffel’s tower served to change construction and engineering forever. Summit Steel Buildings relies on the same methodology for all their work.

Almost six million people visit the Eiffel Tower each year, and almost everyone walks away with an appreciation for the breathtaking views of the City of Light that can only be afforded from the once-tallest building in the world. The metal Parisian tower was the first creation to exceed 1,000 feet in height (300 metres) and is over twice the height of the Pyramid of Cheops (1,063 feet versus 481) and nearly that of the Washington Monument (555 feet). It’s an engineering feat that continues to fascinate and excite visitors from around the globe.

Take a video tour of the Eiffel Tower and experience the view yourself.

What might not be understood by all those visitors is how the engineering used in the construction of the tower became a precursor for all the successful skyscrapers that followed – and for

most industrial buildings being built today. Summit Steel Buildings’ work incorporates these important advancements in every project we do with our teams of skilled tradespeople. We owe a debt of gratitude to the engineering genius behind the iconic French tower for making modern buildings faster to build, safer and less costly.

The race to build the first 1,000-foot structure

A recent episode of “Secrets of the Dead” showcased the competition between the engineering firm of Gustave Eiffel and traditionalist French architects to develop the first thousand-foot structure in the world. Their race to create the showpiece for the 1889 Exposition Universelle (World’s Fair) would ultimately hold significance for engineering and building design for the next century and more.

Watch the full episode, "Eiffel's Race to the Top" on PBS.

Two senior engineers conceived the design for the Eiffel Tower while working for the Compagnie des Établissements Eiffel. The original sketch of their idea was described as "a great pylon, consisting of four lattice girders standing apart at the base and coming together at the top, joined together by metal trusses at regular intervals". Technically a truss tower, the iron lattice engineering offered better wind resistance than stone materials with much greater fire resistance. Eiffel initially showed little enthusiasm, but approved the design once company architect, Stephen Sauvestre, added decorative arches to the base of the tower, a glass pavilion to the first level and other embellishments (source).

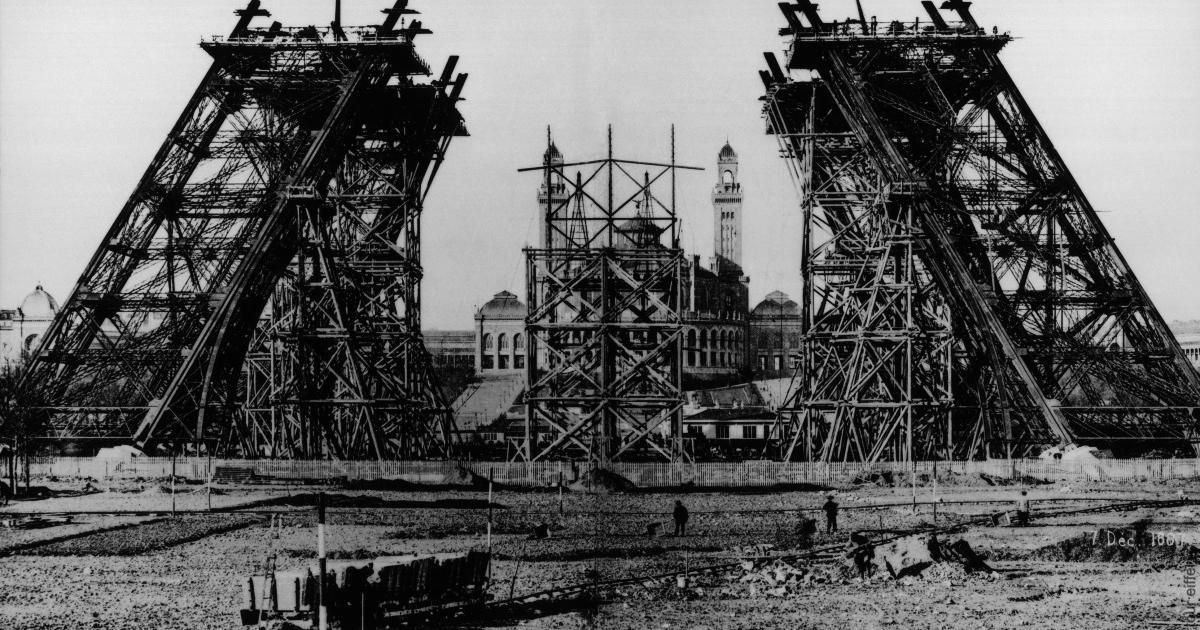

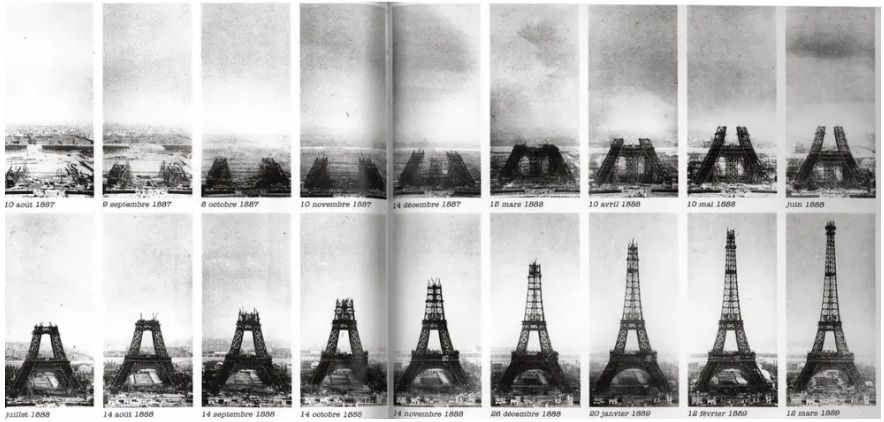

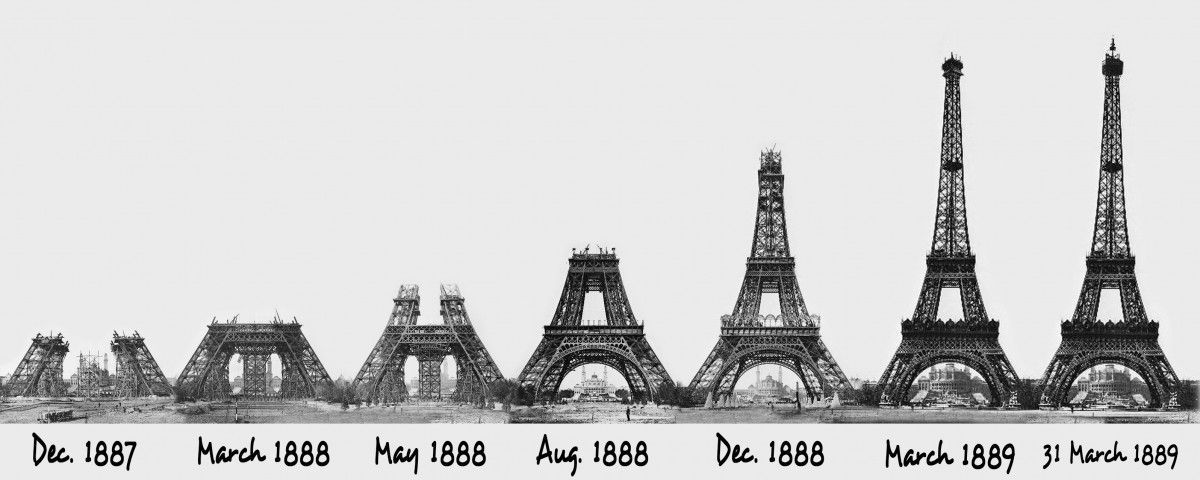

Two of the biggest considerations to win the contest and the contract to build the tower were total budget costs and the timing of completion. Eiffel’s team would only have two to three years to complete construction – something that seemed nearly impossible at the time; especially if using traditional methods and materials like stone and marble. His promise to deliver a turnkey project won the day.

See an

infographic on how long it took to create earlier world masterpieces of architecture, such as St. Peter’s Basilica (199 years), St. Basil’s Cathedral (144 years) and the Taj Mahal (21 years).

Iron unites art and industry

Eiffel’s company was experienced in iron engineering and had developed a streamlined process of manufacturing and pre-fabrication for their all projects. Even in the 1880s, it assured accuracy in manufacturing, precise to tenth of millimetre, while also overcoming objections by being able to be built quickly and on time. The use of an iron framework paved the way for the modern skyscraper and his use of pre-engineering became the foundation of the techniques we use today almost 135 years later.

Eiffel’s process was built on a principle of using an assembly line system to build components, which were flat sheet metal or angled iron, assembling elementary parts and attaching them into sections in a factory a few blocks away from the construction site. Sections were then shipped to location where they were fastened to the rest of the structure for final assembly on site. It is a commonplace process for most current industrial and commercial construction.

One of the key benefits was that pre-engineering required fewer workers on site and could be done safer and faster. A team of constructors, who had previously worked large-scale metal viaduct projects, were responsible for the 150 to 300 workers on site assembling this gigantic erector set. Compare this to the team of 3,400 that were required to complete the Empire State Building built 40 years later and with more casualties (more on that later).

The Eiffel Tower project also included the first use of a small "creeper" cranes installed on each leg. These cranes were designed to move up the tower as construction progressed and made use of the guides for the elevators that were to be fitted in each leg.

Read Part Two of the impact the Eiffel Tower's engineering has had on modern projects:

"Modern impact from Eiffel Tower's engineering"...

About the author

Darren Sperling has specialized in the engineering and delivery of pre-engineered steel buildings for over 15 years and has experience in over 20 countries worldwide. He can be contacted at Summit Steel Buildings at (877) 417-8335, by email at darren.sperling@summitsteelbuildings.com or on LinkedIn.